THE ANILOXADVANTAGEHi-performance Flexo cell technologyConsistent results on every substrate

Founded in 1946 Pamarco Global Graphics, the world’s largest supplier of anilox rolls, has huge experience in the production of laser-engraved anilox rolls and is world renowned for anilox cell technologies for flexo printing and coating. Dantex is Pamarco’s exclusive distributor in Germany, France, Poland and several other countries.

Target for all flexo printers is to ensure that the anilox give correct print density from print number 1 and stays consistent and clean throughout the whole print run. This relies on receiving good advice about which anilox specification is correct for their application and then receiving an anilox which conforms to target and has a cell profile with excellent ink transfer. Pamarco has conducted extensive banded roll trials and this combined with considerable field knowledge has enabled this unique cell technology, to be applied successfully into various printing markets such as corrugated paper, flexible packaging and UV flexo.

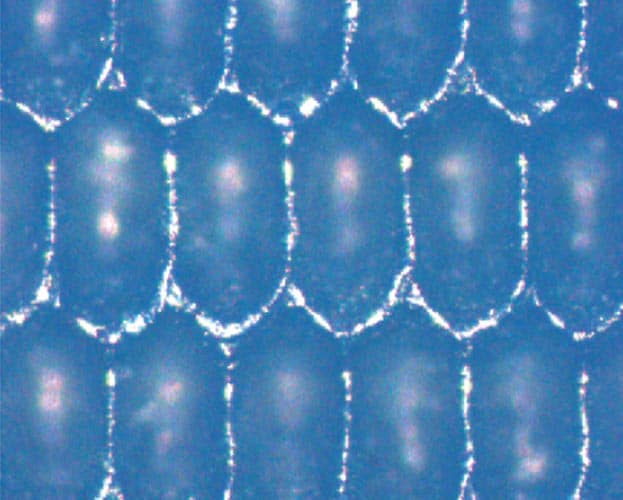

EFlo – 75 degree

EFlo technology is a high-performance anilox engraving, developed to meet the increasing demand for the highest quality print. EFlo has an extended 75° cell geometry; its elongated cell walls allow for increased ink transfer compared to the conventional hexagonal cell shape. Its ability to release a larger amount of ink helps to achieve a higher solid coverage and reduces the chance of cell plugging. It is ideal for use within faster press speed environments.

EFlo improves print quality by enabling printers to use a horizontal line screen count that is 30‐40% higher than traditional 60° engravings, at the same volume. By increasing the number of cell walls across the cylinder, printing of screens, fine type and solids is improved.

The benefits of EFlo Technology:

- Extended cells for larger cell volume at finer screens.

- Consistent thin walls for smooth ink doctoring, low wear and scoring.

- Flat level cell base, to ensure high ink release in any direction or configuration.

- Anilox cells that print clean and stay clean.

- HD Certified, designed to work with high-resolution HD digital plate technology.

- Easy to maintain.

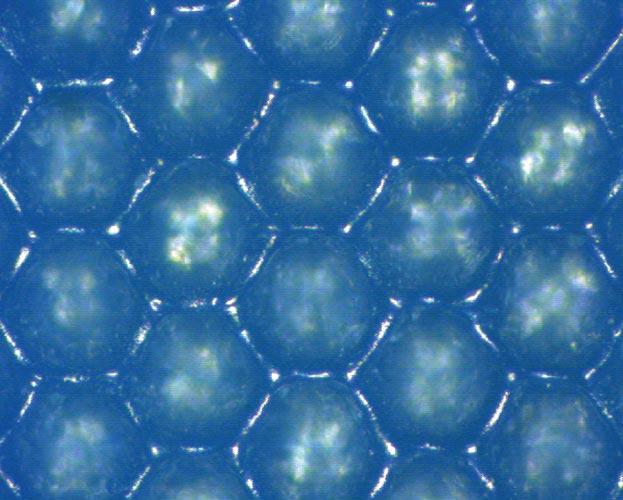

ThermaFlo – 60 degree

ThermaFlo is a 60ᴼ multi-hit honeycomb cell engraving. Its smoother, more consistent cell wall geometry offers better uniformity and accurate ink metering capabilities. It also allows for better resistance to scoring and wearing, which helps to achieve a longer life for your anilox.

ThermaFlo is all about giving you better control and consistency; this has become essential for the printing of highly detailed graphics, especially within the flexible packaging and narrow web markets.

The benefits of ThermaFlo:

- Solid state, multi-hit fibre-optic technology.

- Improved resistance to doctor blade scoring, due to the surface hardness of the ceramic.

- Extended volume ranges due to multi-hit technology.

EFlo UV – 75 degree

EFlo UV is Pamarco’s latest anilox cell engraving and has so far proven to deliver outstanding ink transfer capabilities for the most demanding of applications, especially within the narrow web and label markets. Like EFlo, EFlo UV has a 75ᴼangle; however, what differentiates EFlo UV from the other standard cell technologies we offer is its channel-linked cell geometry. The precision channel between the cells helps to eliminate the build-up of pressure within the ink when doctored, which can generate ink spitting.

EFlo UV can be engraved with finer screens and can maintain higher volumes in comparison to standard cell geometries. This technology ultimately offers improved print quality and consistency for the converter.

The benefits of EFlo UV:

- Open cell geometry delivers a controlled ink film to the printing plate, eliminating the chance of spitting.

- EFlo UV can deliver a higher volume of ink compared to 60° hexagon cells while maintaining print fidelity.

- Cells are engraved at a consistent angle of 75ᴼ, which ensures no screen clash with standard flexo plate screen angles.

- Allows for higher screen counts without compromising depth to opening ratios, maintains good support to Flexo plate dots and provides excellent ink film thickness to the printing plate.

- Helps keep anilox cells cleaner for longer, reducing downtime and improving consistency.

Do you have an enquiry about Anilox Technology?

Please fill the form below and we will get in touch.

Related Products

AQF Combination Processor

Digital Plate Combination Processor

Torelief

Letterpress Waterwash Plate

Varnica

Dedicated to coating/varnish applications

Star Plate

Chemistry-free HD films from inkjet devices

AQFC Plate Cleaners

For Letterpress and Flexo Plates

Rotunda – Magnetic Plate Cleaner

For cleaning metallic photopolymer plates

Aquaflex

Flexographic Waterwash Plate

AQF – Plate Processors

Water Wash Plate Processor

Marathon

UV Inkjet Label Press